Many experienced logistics professionals say that tendering logistics services is partly art and science – this is certainly our sentiment as well.

We wanted to take a brief moment to share with you some of the stories, experiences and thoughts around this very important and common topic of tendering 3PL logistics services, in this case warehousing operations.

When it comes to the process of tendering itself, the very main step is to identify the scope of services that would be submitted to the competitive market – this in most cases requires qualitative and quantitative data gathering. These exercises are often times tedious and many people within the organization throw this responsibility over the fence to their neighbors – clarity, brevity and simplicity are usually the best strategies to come out unscathed through this stage of the project.

This often underestimated and unpopular step in the tendering process can have a critical impact on the success or failure of a newly established business relationship with a 3PL after having negotiated a contract and implemented the final solution.

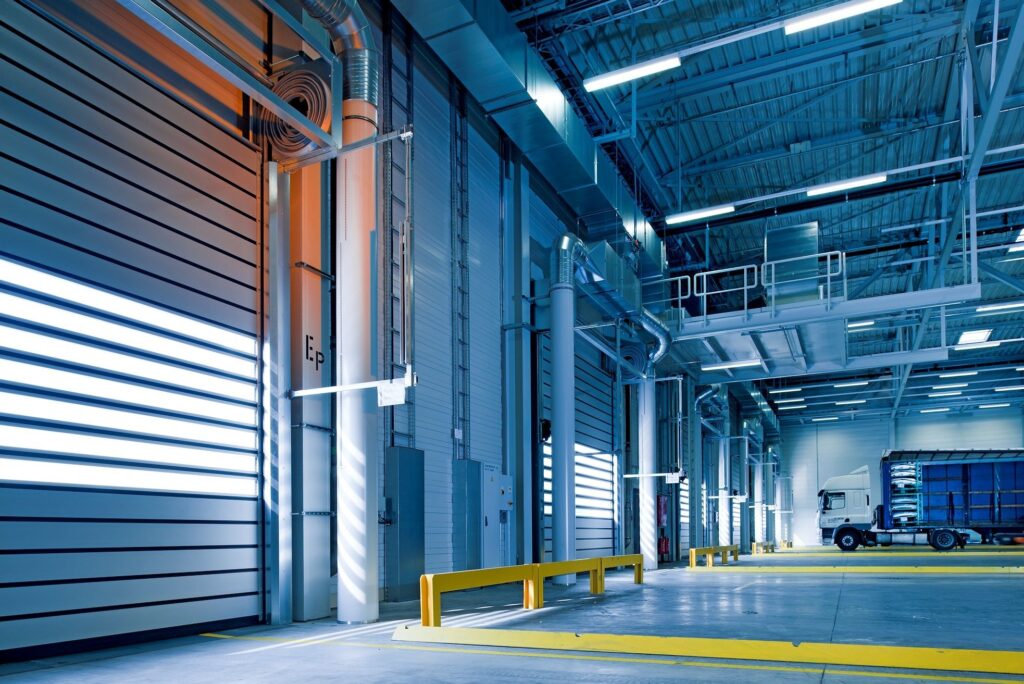

Case in point from an experience that we’ve heard from one of our clients. The project was meant to deliver a green-field facility with a considerable amount of automated solution for an FMCG product portfolio. The awarded supplier has dutifully fulfilled its expectation to provide a solution based on the submitted requirements, descriptive and volumes based, and built a commercial budget accordingly which became the basis for the upcoming cooperation.

Through the final phase of the project, which were the operational workshops through which the teams would create the underlying logistics concept for the operation, came unexpected and unpleasant surprises. What the teams realized is that the productivity assumptions for the automated AGV solution (used for moving the pallets from the docking area to the storage areas) did not take into account the dynamic working conditions of the machines but rather were based on static environment which would never reflect this fast moving operation.

Suffice to say that this blunder has created a domino effect which spilled into the other elements of the commercial offer and resulted in essentially going back to square one of the tendering process where the entire solution and the corresponding budget would have to be recreated.

Lesson learned – it is critical to also account for the time needed in the tendering project to pressure test some the more important operational assumptions with 3PLs in the final round of the project. This will allow for potentially adjusting the final award to the 3PL that is better equipped and able to reflect real-life considerations in their solutions design, commercial offer and ultimately delivery of the services that the client expects and demands.